ZANDAIR Portable Air Purification

The need for filtered air has never been more important. No matter how well you maintain your laboratory, your work area can be filled with air pollutants, volatile organic compounds (VOCs), chemically active compounds (CACs), aldehydes, carcinogenic materials, carbon monoxide, viruses and bacteria, dust particles, mold spores, cleaning chemicals, and more.

All these airborne pathogens can affect your IVF outcomes and the health of workers in the laboratory. Protect your lab with effective air filtration from ZANDAIR!

- 4-step air purification cleans air down to the last molecule

- Hospital grade high efficiency filter removes microparticles

- Photocatalytic oxidation destroys toxic chemicals and eliminates odors

- Ultraviolet light attacks the molecular structure of viruses and bacteria

- Human

- Animal

Applications

- IVF laboratories

- Culture environments

- Embryo development

Specifications

| ZANDAIR 100C | Catalyst: Metal Oxides |

| UVC Wavelength | 254 nm (produces no ozone) |

| Particle Filter | HEPA filter |

| Gas Adsorption | Activated Charcoal |

| Max Air Flow | 265 CFM/7.5m3 per minute |

| Application | 1,000 Cubic feet max./ 29 cubic meters |

| Dimensions | 55cm X 46cm X 20cm |

| Weight | 10.43 kg |

| Power Requirements | 120v – 60hz /220v – 50hz |

| Max Watts | 110 watts |

Features & Benefits

The ZANDAIR™ 100C CLEAN AIR Photocatalytic Air Purification System is a portable unit specifically developed to meet the demands of IVF laboratories. Air quality is critical to embryo development and overall success of IVF. Studies show that poor laboratory air quality can result in decreased birth rates and poor IVF outcomes.

This portable air purifier easily fits into your lab and provides effective air filtration with a small footprint.

ZANDAIR™ 100C Components:

- Activated carbon filter

- HEPA filter to remove particles down to 0.3 um

- Photocatalytic oxidation chamber

- High output UVC lamp

- High efficiency low noise reversed curved motorized impeller with sealed ball bearings.

The integrated UVC lamp has an output in the 254-nanometer wavelength range. This wavelength destroys bacteria and viruses while still remaining within a safe range WITHOUT producing ozone.

Electronic sensors monitor air quality and automatically increase the performance of the air purification system to compensate for periods of unusually high chemical activity and increased human activity.

Warning lights alert staff to the presence of toxic chemicals and fumes well before they reach dangerous levels or become detectable to the human senses.

Process

The key to effective air filtration is Photocatalytic Oxidation.

The chemical compounds of damaging VOCs become highly reactive when exposed to a specific wavelength of ultraviolet light. The photocatalyst attracts pollutants and converts them into benign compounds such as water (H2O) and carbon dioxide (CO2). The catalyst will not wear out and maintains its effectiveness after the process.

STEP ONE: Adsorbs Toxic Chemicals and Gases

The front position Activated Carbon Filter with specially formulated gas adsorption media (including zeolite and potassium permanganate) adsorbs volatile organic compounds (VOCs), chemically active compounds (CACs), and other harmful agents.

STEP TWO: Hospital Grade High Efficiency Filter Removes Microparticles

A Back-Position Hospital Grade High Efficiency Filter individually tested by the supplier and certified to remove particles down to 0.3 µm.

STEP THREE: Photocatalytic Oxidation Destroys Toxic Chemicals and Eliminates Odors

Photocatalytic Oxidation converts toxic malignant compounds (even carbon monoxide and nitrous oxide) into benign compounds such as water (H2O) and carbon dioxide (CO2).

STEP FOUR: Ultraviolet Light

Ultraviolet light attacks the molecular structure of viruses and bacteria, which are too small to be filtered out by the High Efficiency filter, thus rendering them harmless. UV light converts VOCs and CACs into H2O and CO2. Ultraviolet light technology combined with Photocatalytic-Oxidation is an important and unique feature of this air purification / filtration system.

Resources

Get Instant Access

Enter your information below to view this resource.

"*" indicates required fields

Are you a Hamilton Thorne distributor?

Sign in to the distributor portal to gain access to all gated assets and exclusive content.

Applications

- Forensic Laboratories

- Pathology Laboratories

Specifications

| ZANDAIR 100P | Catalyst: Metal Oxides |

| UVC Wavelength | 254 nm (produces no ozone) |

| Particle Filter | HEPA filter |

| Gas Adsorption | Two (2) Activated carbon media |

| Max Air Flow | 265 CFM/7.5m3 per minute |

| Application | 1,000 Cubic feet max./ 29 cubic meters |

| Dimensions | 55cm X 46cm X 20cm |

| Weight | 10.43 kg |

| Power Requirements | 120v – 60hz /220v – 50hz |

| Max Watts | 110 watts |

Features & Benefits

The ZANDAIRTM 100P CLEAN AIR Purification System is a portable unit, specifically developed to meet the demands in anatomical pathology and forensic laboratories where formalin and other toxic hydrocarbons are prevalent. This air purifier is most effective in areas where pathology chemicals are used and regular refilling for automated and manual slide stainers and processors are required.

This portable air purifier easily fits into your lab and provides effective air filtration with a small footprint.

ZANDAIR™ 100P Components

- 2 activated carbon filters

- Photocatalytic oxidation chamber

- High output UVC lamp

- High efficiency low noise reversed curved motorized impeller with sealed ball bearings.

The integrated UVC lamp has an output in the 254-nanometer wavelength range. This wavelength destroys bacteria and viruses while still remaining within a safe range WITHOUT producing ozone.

Electronic sensors monitor air quality and automatically increase the performance of the air purification system to compensate for periods of unusually high chemical activity and increased human activity.

Warning lights alert staff to the presence of toxic chemicals and fumes well before they reach dangerous levels or become detectable to the human senses.

Process

STEP ONE: Adsorbs Toxic Chemicals and Gases

The front position Activated Carbon Filter with specially formulated gas adsorption media (including zeolite and potassium permanganate) adsorbs volatile organic compounds (VOCs), chemically active compounds (CACs), and other harmful agents.

STEP TWO: Higher Adsorption of VOCs and CACs

A second Activated Carbon Filter increases the ‘dwell time’ providing a higher adsorption of VOCs and CACs.

STEP THREE: Photocatalytic Oxidation Destroys Toxic Chemicals and Eliminates Odors

Photocatalytic Oxidation converts toxic malignant compounds (even carbon monoxide and nitrous oxide) into benign compounds such as water (H2O) and carbon dioxide (CO2).

STEP FOUR: Ultraviolet Light

Ultraviolet light attacks the molecular structure of viruses and bacteria, which are too small to be filtered out by the High Efficiency filter, thus rendering them harmless. UV light converts VOCs and CACs into H2O and CO2. Ultraviolet light technology combined with Photocatalytic-Oxidation is an important and unique feature of this air purification / filtration system.

Resources

Get Instant Access

Enter your information below to view this resource.

"*" indicates required fields

Are you a Hamilton Thorne distributor?

Sign in to the distributor portal to gain access to all gated assets and exclusive content.

You may also be looking for

Case Studies

How other labs have utilized Hamilton Thorne solutions

New Mexico Cryobank and Andrology Lab (Roosters)

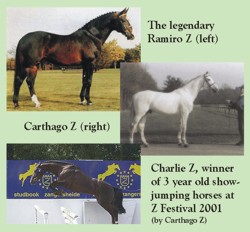

Zangersheide N. V. (Equine)